Diesel Engine Fuel System Diagram

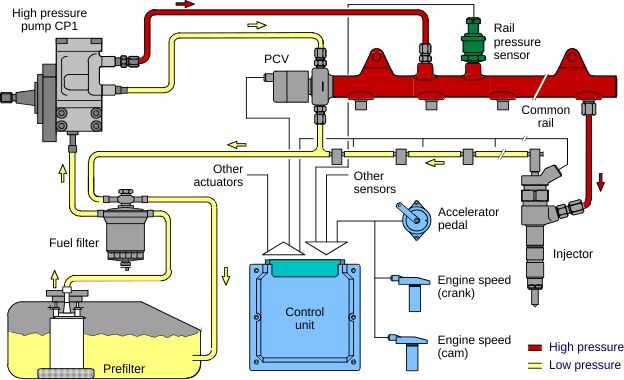

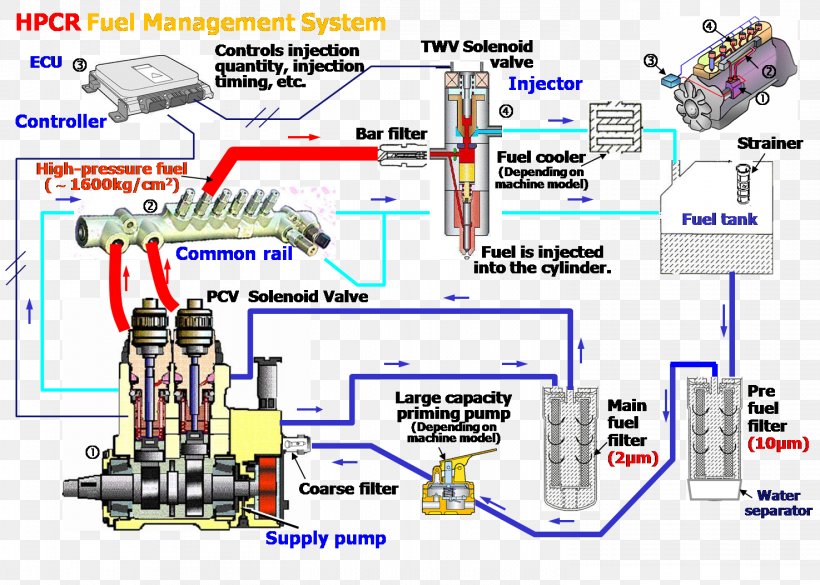

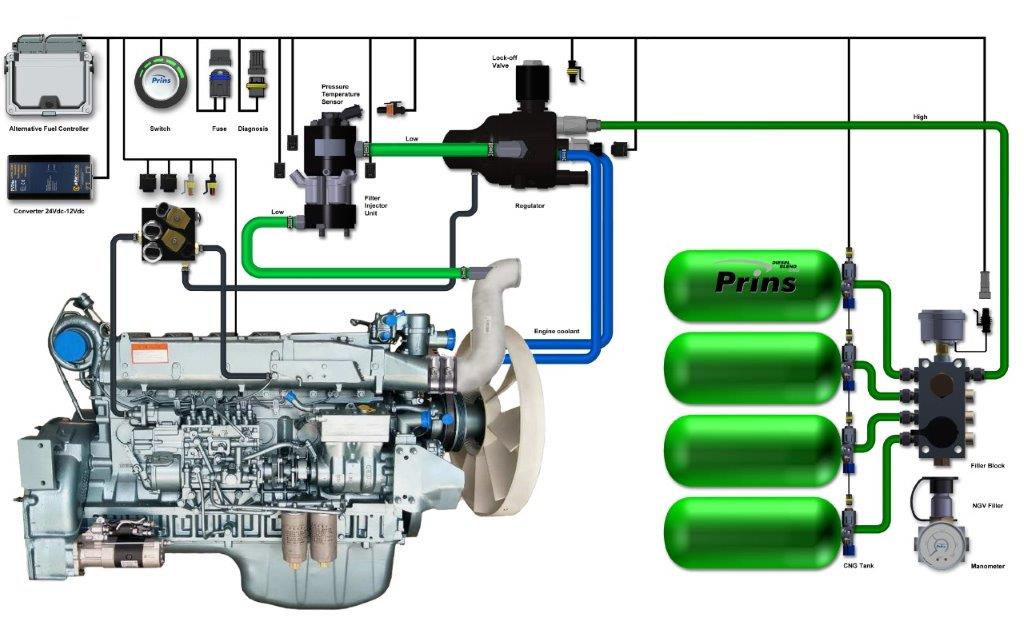

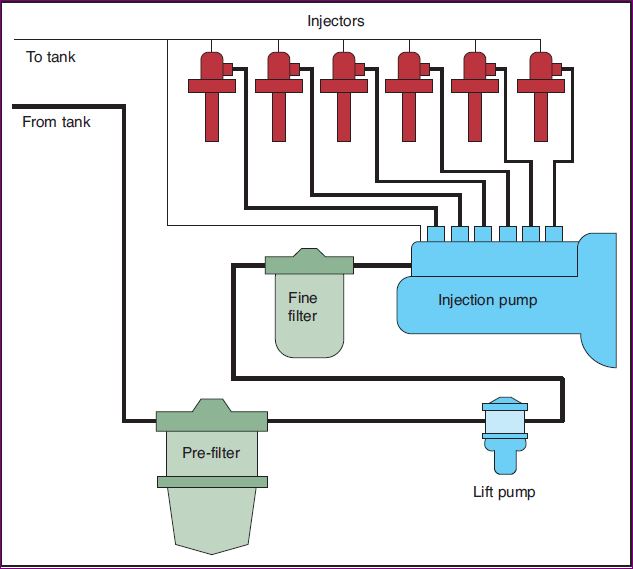

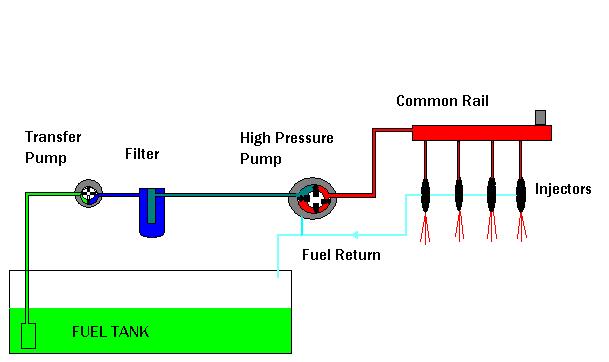

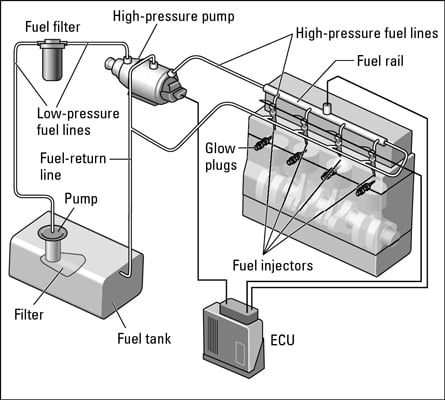

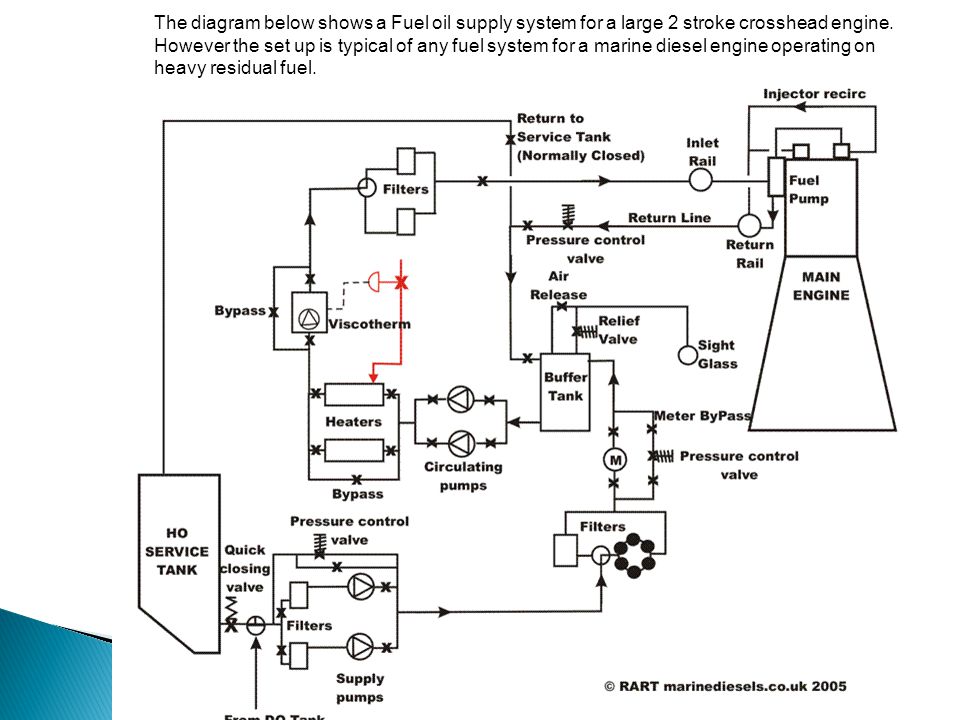

Diesel engine fuel system diagram. However by the late 1970s with the raising cost of diesel fuel and the inefficiencies inherent in their 2-Stroke Cycle engines which resulted in them consuming more diesel fuel than their competitors modern 4-Stroke Cycle engines Detroit. The purpose of the fuel injection system is to deliver fuel into the engine cylinders while precisely controlling the injection timing fuel atomization and other parametersThe main types of injection systems include pump-line-nozzle unit injector and common rail. The diesel engine named after Rudolf Diesel is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to the mechanical compression.

Detroit Diesel DDC had been building only 2-Stroke Cycle engines such as the venerable 6-71 since General Motors created the division in 1938. Each has its own advantages and disadvantages. Due to this reason the producer gas cannot ignite by itself under normal pressure.

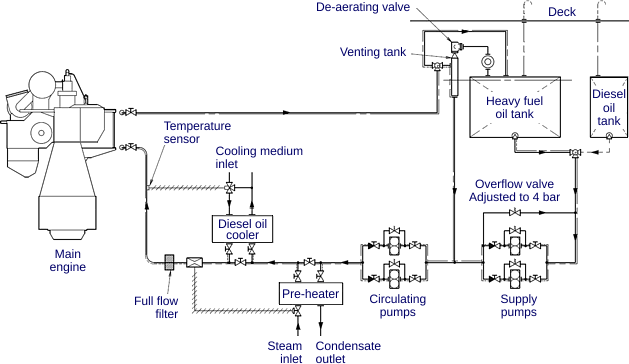

When fuel is injected it vaporizes and ignites due to the heat created by the. There are three possible routes for fuel to enter the lubrication system. The following link by the Kruse Technology Partnership describes the four-stroke diesel cycle operation including a.

Do not open a fuel system under high pressure. The fuel injection pump is fed with fuel in abundance. The diesel engine is used in heavy vehicles like Car Trucks Generator and Buses extra.

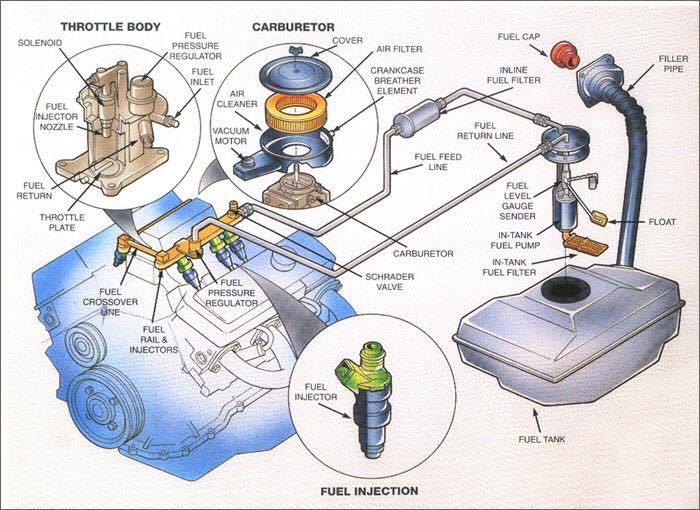

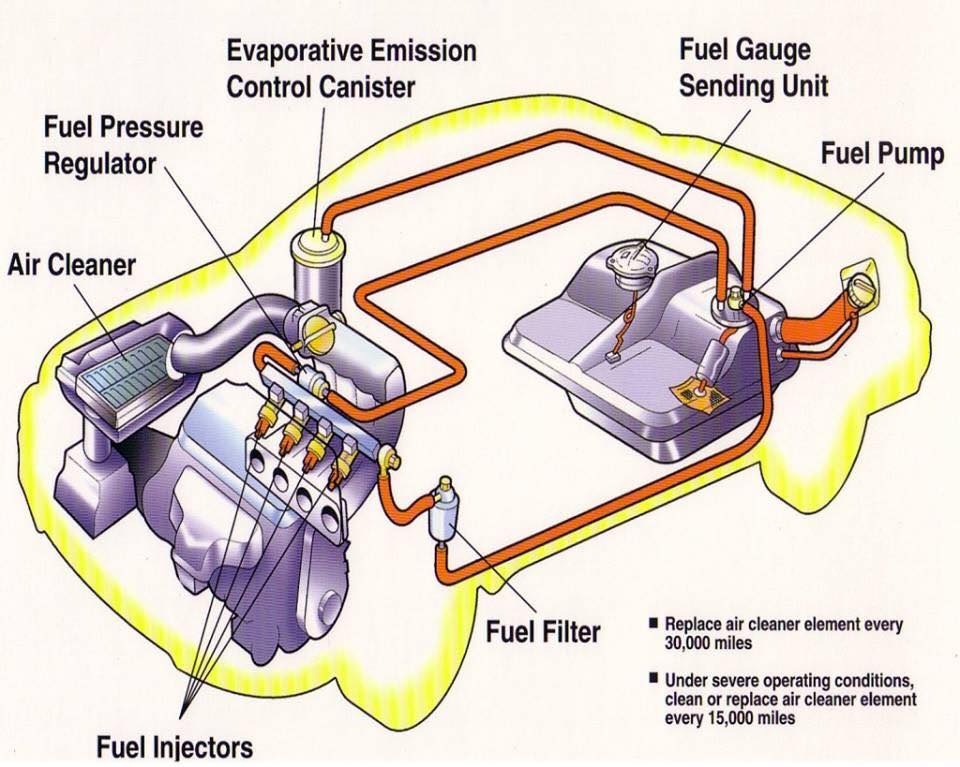

Modern injection systems reach very high injection pressures and utilize sophisticated electronic control methods. Wiring Diagram. 1 fuel filter 2 fuel lift pump 3 fuel injection pump 4 atomisers and 5 high pressure pipe.

Correction I have a 16 hp twin briggs pig ordered a new coil as the one the motor had was burnt at the ground and wires where coming from inside the plastic. The excess fuel is by-passed to the intake side of the fuel transfer pump through a relief valve. Thus the diesel engine is a so-called compression-ignition engine CI engine.

There is also the external combustion engineThe steam engine in old-fashioned trains and steam boats is the best example of an external combustion engine. E-ZOIL manufactures several additives formulated to address common issues encountered by the diesel fuel system.

Each has its own advantages and disadvantages.

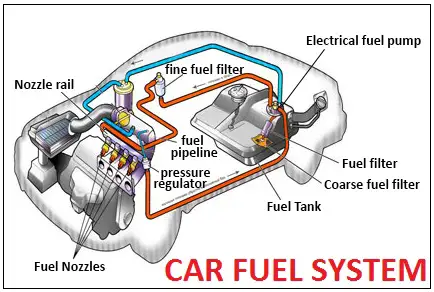

Read more about 30 Basic parts of a car with a diagram. Diesel Engine has the lowest. Dual cycle engine or semi-diesel cycle engine. TO THE READER. Correction I have a 16 hp twin briggs pig ordered a new coil as the one the motor had was burnt at the ground and wires where coming from inside the plastic. Wiring Diagram. The diesel cycle produces more amount of power compared with less fuel to the Otto cycle. Can be caused by a plugged fuel filter low fuel supply pressure high pressure side fuel system leakage. The excess fuel is by-passed to the intake side of the fuel transfer pump through a relief valve.

E-ZOIL manufactures several additives formulated to address common issues encountered by the diesel fuel system. Pistons pump up and down as the spark plugs fire and the pistons compress the airfuel mix. The following link by the Kruse Technology Partnership describes the four-stroke diesel cycle operation including a. An increase of volumetric fuel consumption is observed with HVO in all operating points ranging from 2 to 8. The diesel engine is used in heavy vehicles like Car Trucks Generator and Buses extra. Due to this reason the producer gas cannot ignite by itself under normal pressure. The List of Auto parts Parts of an Engine.

Post a Comment for "Diesel Engine Fuel System Diagram"